FAQ

Analysers

Can I control the Microcell system from Solartron software?

There are two possibilities:

If Modulab devices are used with the Modulab software, the thermo controller can be directly implemented via the "Eurotherm" device control. (See Modulab manual).

If older instruments are used in combination with SMART or CorrWare Software, the system is controlled via the "RUN EXTERNAL APPLICATION" command. We offer our "HC Control" software free of charge for this purpose. Please contact us.

PAR devices: How do I set up the temperature controller?

If no other serial device is connected to the computer, use the native COM port or set our USB to serial adapter (Moxa) to COM 1, by using the UPort configuration utility under Start->All Apps->Moxa. Next, start HC Control and try to manually set the temperature. If this works, start the PAR software.

Here, set up any measurement routine and include the "Run External Application" command. Chose the path where hc_control.exe was installed and use the command line parameters as given in the HC Control manual. IMPORTANT: In Versastudio, set "Wait" to "Yes" in the options for "Run External Application"!

How can devices of different manufacturers communicate with the Microcell HC setup (= automated T-adjustment during procedures)?

- Autolab: Perfectly integrated, no additional software needed.

- BioLogic: Works very well, but a small converter box (analog in/out to serial) from RHD is needed.

- Solartron (Modulab!): Works very well, controller already embedded in Software.

- PAR, old Solartron (1260): Works well with a software called HC_control from RHD.

- Zahner: Works well, small additional program to embed VI from RHD needed.

- Novocontrol: Works very well, but a small converter box (modbus to bysinc) from RHD is needed.

- Gamry: Works only manual Adjustment.

Applications

What kind of dry gas regulators should be used with the faraday cage?

If measurements below the ambient dew point are to be performed, the cage needs some source of dry air or protective gas. From our experience, most compressed air outlets offer a pressure around 1 MPa (10 bar, 145 psi). This is too much pressure to apply to the cage. Therefore, any kind of pressure regulator can be used that can be set to 10 kPa (0.1 bar, 1.5 psi) and where one can regulate the gas stream.

The dry gas should only slightly flow through the cage. There is no specific outlet valve, the gas is streaming through the gaps at the door.

How long does it take until the dew point is low in the cage?

It takes only a few minutes until the dew point is lowered significantly.

I added solid, or ferrocene solution in acetonitrile to the ionic liquid but I don't see any CV peak for ferrocene. Why?

It takes some time for ferrocene to dissolve in ILs. We would suggest to add a small amount of Fc solution in the same or a similar IL and make sure the two liquids are mixed sufficiently.

Also, try to measure a freshly prepared Fc IL solution on freshly polished electrodes without prior CVs in the pure IL. This is to make sure your hidden Fc peak is not due to any passivation layers formed on the electrode.

Also make sure that the electrochemical window of your IL is large enough to observe the Fc peak within.

When or why should I use a Faraday cage? What advantage brings the dew point sensor?

In the first place, the faraday cage is used if low currents are to be measured or if a high level of electrical noise is present, like in a lab with lots of different devices running.

The dew point sensor option comes into play when long-term measurements at lower temperatures are planned. If the Microcell system is set to -20 °C for a longer time, the humidity from the air will condensate and freeze subsequently, leading to ice formation on the cell.

This can be disadvantageous because water can cause connection problems and almost all energy from the Peltier element is consumed for ice formation.

Such situations can be avoided if the dew point around the system is lowered close to or below the measuring temperature. Both types of Faraday cages from rhd instruments can be connected to dry gas, but with the dew point sensor option, the atmosphere can easily be monitored.

How do I perform automated conductivity measurements within a wide temperature range, e.g from -40 °C to +70 °C?

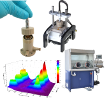

If you use the Metrohm NOVA software to perform online fits to an equivalent circuit, it is likely that this will not work for the complete temperature range since the shape of the impedance spectrum might vary significantly either due to phase transitions of the material, like e.g. freezing, or due to a significant change of time constants leading to a shift of the features visible in the impedance spectra. Therefore, we suggest that the temperature range is divided into parts like -40 °C to -20 °C, -20 °C to 0 °C, and so on. Then, at the first temperature of each section, e.g. -40 °C, an impedance spectrum ranging from e.g. 1 MHz down to 0.1 Hz should be recorded using the standard, unmodified NOVA procedure "FRA impedance potentiostatic" to get a feeling about how the system behaves and how the spectrum looks like. The spectrum should then be fitted using a suitable equivalent circuit. If a proper, reasonable circuit has been found, it can then be used for the procedure including automated temperature control and the online impedance data analysis.

Alternatively, you can carry out the temperature-dependent measurements without performing online data analysis routines. Afterwards, use RelaxIS for evaluating the impedance data. That is the way we carry out experiments at our site since there are several advantages: (i) The measurements are faster if the online data analysis step is left out and (ii) sometimes the impedance spectra are complicated and in that case RelaxIS offers very powerful tools ("Auto Fit") to get a good fit result. (iii) Moreover, it is easier to manage the data.

How to determine the cell constant of liquid sample cells

Record an impedance spectrum (2 electrode configuration) for your

cell filled with a conductivity standard at a defined temperature

(typically 20 °C or 25 °C). Then evaluate the impedance data to extract

your bulk resistance value. To calculate the cell constant, you proceed as

follows:

Cell constant = bulk resistance determined by EIS @ measuring temperature x

conductivity given by manufacturer @ measuring temperature

How long does it take until the sample reaches thermal equilibrium after performing a temperature step?

The required hold time after a temperature step depends on the sample's properties (heat transfer coefficient etc.) and the sample volume/mass.

As a rule of thumb, 300 to 600 s for liquid samples of low viscosity,

600 to 900 s for liquid samples of medium viscosity, 900 to 1800 s for liquid

samples of high viscosity and polymeric samples and 1800 to 3600 s for solid

samples should be sufficient.

There are two different ways to check if the hold time is sufficient:

(i) One can peform a typical temperature jump and record consecutive EIS

spectra. The time required until the EIS spectrum does not change anymore +

a buffer of 25% should be ok.

(ii) One can plan the experiment so that a heating ramp is followed by a cooling ramp. If there are no phase changes or Degradation processes, the spectra measured for the same temperature at heating and cooling ramp should be more or less identical.

Cell Stands

What causes the periodical changes in the OCP value while using the Microcell HC temperature control?

Periodical changes in OCP values in the seconds range and an amplitude in the µV regime is often due to stray pickup from the Peltier electronics. It can be reduced significantly if the setup is placed in a Faraday cage and, more importantly, the cell stand as well as the shielding of the Connection Box is connected to the virtual ground of the instrument.

What certificates apply to the Microcell HC setup?

The Microcell HC setup as well as accessories like the cooling box or dew point sensor comply with DIN EN 61010-1 VDE 0411-1:2011-07 (IEC 61010-1:2010 + Cor.:2011). On this basis, the CE label is placed on the products.

The products are research instruments designed for laboratory experimentation and not destined for the consumer market.

The products are research instruments designed for laboratory experimentation and not destined for the consumer market.

Measuring Cells

What are gold plated stainless steel electrodes used for?

The gold plated disc electrodes are very useful if electrode/sample/electrode sandwiches should be prepared beforehand. Usually, this is the case when polymers or gels are to be measured or when stainless steel is not stable in contact with the sample.

In case of thermoplastic polymers, they can be melted between two disc electrodes and the distance maintained by suitable spacer materials.

How to perform conductivity measurements with soft matter?

The best way is to use the TSC battery cell in combination with the spacer set. Doing so, the distance as well as the area of the electrodes is kept constant at all times, hence the calculated cell constant can be used.

Can the metal pseudo reference electrodes for the TSC 1600 be used with the TSC Battery?

This Pt reference is designed to be used with the TSC 1600. However, it can also be used it with the TSC Battery, together with the capillary screw fitting.

Care must be taken not to short circuit the reference electrode with the other electrodes, since the wire will be reaching slightly inbetween the battery electrodes. In any case, this works only in combination with thick fiber glass separators (the reference wire is "sandwiched" between separator layers).

As an alternative, the wire can also be shortened by the customer to fit better into the battery cell.

TSC Battery: How to handle the Lithium reference fitting?

Put a small piece of Li metal into the little cavity at the tip of the Li reference fitting. Use tweezers or a little spatula to press the lithium against the stainless steel back connector. Make sure no Li sticks out of the cavity. In this way, short circuit protection is provided by the peek tip of the reference electrode fitting.

If fibre-based separators are to be used, a small piece of separator material in front of the Li reference can be helpful.

TSC Battery: What is the best sample diameter?

The maximum diameter for samples is 12 mm. However, if a punching tool is used, one often finds that the resulting specimens have a slightly larger diameter caused by a bending of the foil during the punching step. Therefore, we recommend to use a punching tool with e.g. 11.8 mm inner diameter.

When building batteries it should also work if 12 mm diameter separator foil is prepared and combined with active material having a smaller diameter like e.g. 11 mm.

TSC Battery: How to check connections and internal resistance?

There is a 100 Ohms test resistor available from rhd instruments. This disc-shaped resistor with a diameter of 12 mm fits perfectly into the TSC Battery. Put the disc between the plane current collector electrodes (not the ones with punching edge) instead of the sample and perform the measurement. Substract 100 Ohms from the obtained Z' value to get the internal ohmic resistance of the cell and connections.

This is especially useful when samples with very low impedances are to be measured.

What kind of disc electrodes shoul I use? Stainless, nickel or gold plated?

Stainless is mostly suited for non-aggressive samples. In general, the disc electrodes are to be used when gels, polymers or "sticky" samples should be measured. The disc electrodes work as a protection of the built-in current collectors of the cell.

If thermoplastic polymers or gels are used, an electrode/sample/electrode sandwich can be easily prepared and also stored after the measurement for longterm investigations.

Gold plating is always useful if the sample contains chloride ions while nickel is used for samples containing sulfides.

What spacers should I use with the TSC battery or TSC SW closed?

Ring-shaped spacers are available in different thicknesses from 25 µm to 200 µm. They are used for gels or polymeric samples. The material is PEEK or PET. If the polymer to be measured has a low dielectric constant, quartz fibre spacers are also available in 319 µm thickness.

TSC 1600: What are typical cell constants?

The cell constants vary for different electrodes in the screw cap. In case of the 0.25 mm Pt electrodes, typical values lie around 16-19 1/cm, in case of the 3 mm exchangeable electrodes, the cell constant is around 1.2 to 1.4 1/cm.

We stronlgy recomment to check the cell constants for every combination of cell body and screw cap.

What electrode cap should I use with TSC1600, Pt or GC?

If the samples contain HF, like some battery electrolytes do, the TSC 1600 has to be used in combination with the GC cap since HF causes severe glass

corrosion. For all other liquid samples, both caps should work. However,

since the active surface in case of the GC electrode cap is larger, it

should also be preferred if a relatively low conductivity is expected.

Both caps have their advantages:

The Pt cap offers 4 separately connectable electrodes. If CV measurements are also carried out, one Pt electrode can be used as WE

and another one as RE. Furthermore, if the WE is "poisoned" by the formation

of an ad-layer during the CV measurement which alters the shape of the

resulting CV, it can be easily switched to another fresh WE without

opening the cell by just connecting one of the two remaining Pt wires.

The GC electrode tip on the other side can be removed from the cap and

be coated with a customer-specific substance, forming a new type of WE. Furthermore, since electrode tips with other electrode materials

are available at RHD, the GC tip can easily be exchanged by a Pt tip for example within a few seconds.

What is the maximum heigth of a sample in TSC Battery?

We recommend that the height of the sample should not exceed 3 mm if you

want to start at almost "pressure-less" conditions which means that you have

a very low contact pressure. Nevertheless,

also thicker samples can be used. Without any disk electrodes, you could

also use samples as thick as 8 mm, taking then into account the contract

pressure. If additional metal disc electrodes are used, their thickness has to be taken into account.

In general, one also has to bear in mind that thicker samples will lead to

higher resistance/impedance values which also limits the maximum sample

thickness. In combination with most impedance analyzers, the expected impedance should not be much larger than 1 GOhm in order to get spectra with low noise level.

What is the spring constant of the contact spring in the TSC Battery / Sw Closed?

Two different springs are available for the cells:

- A soft spring with a spring constant of: 2.3 N/mm

- A strong spring with a spring constant of: 32.6 N/mm

Before purchase, we assist in selecting the spring that is best suitable for your application.

How should I unload and clean the measuring cells TSC 70 closed and TSC 1600 closed?

After finishing a measurement, the following steps should be performed (please wear protective glasses, gloves and laboratory coat):

- Open the cell by unscrewing the cap from the PEEK housing.

- Extract residual electrolyte from the platinum crucible by using a plastic syringe w/o needle to avoid causing scratches.

- Take a cotton pad soaked with suitable solvent (depends on the chemistry of the sample; e.g. in case of cabonate-based battery electrolytes use acetone) and wipe out the platinum crucible and carefully wipe the surface of the electrode in the cap.

- Remove the fittings from the cap and clean them as well as the boreholes for the fittings in the cap.

- Loose the three screws at the bottom and remove the PEEK housing from the gold-plated cell core.

- Remove the o-rings.

- Take a cotton pad soaked with suitable solvent and wipe out the inner side of the PEEK housing and also clean the outer part of the gold plated core.

- Clean the o-rings as well as the channels for the o-rings of the PEEK housing.

- Make sure that you wear protective glasses! Take the hand-hold electric tool ("dremel"), insert and fix (!) a "polishing stick" (= Q-tip cut into two pieces), apply a (very) small amount of polishing paste (250 nm particle size) to the cotton tip of the stick and let it spin at the lowest (!) rotation speed. Carefully polish the platinum crucible as well as the surface of the electrode in the cap.

- Take a cotton pad soaked with a suitable solvent and wipe out the platinum crucible and clean the electrode in the cap.

- Perform step 10 several times until the residual polishing paste is completely removed.

- Take a suitable plastic or glass shell and transfer all parts to a vacuum oven.

- Have a look at the o-rings and make sure that they are not swollen or damaged. Otherwise, take new ones. O-Rings made of EPDM work for almost all cases. In the current version of the measuring cell manual, a table with a rough overview of the compatibility of o-ring materials with different solvent systems can be found.

- Dry the cell parts at e.g. 60 °C for several hours, e.g. overnight.

- Transfer the parts into the glovebox and assemble it there.

- The PEEK housing, o-rings and fittings can also be cleaned in an ultrasonic bath.

- Do NOT clean the gold-plated cell core and the complete cap in an ultrasonic bath. Otherwise, the Pt100 sensor or the electrode in the cap (glass + 4 x Pt) might be damaged.

- Make sure that neither heat conductive paste nor sample or salt containing liquid enters the USB-connector of the cell.

- Do NOT leave the cell assembled after a measurement for a longer period. Sample entering the gap between PEEK housing and gold-plated cell core might lead to severe corrosion.

TSC battery: What cell constant should be used when measuring the 100 ohm test resistor?

Ther is no need for a cell constant when measuring the 100 ohm resistor. The cell constant is only required when measuring a real sample for which the dc ion conductivity should be determined. The 100 ohm test resistor is typically measured to obtain the internal resistance of the cell and all connections in order to subtract this resistance from low impedance sample measurements.

Software

HC Control can't open the COM port. Why?

This message appears in HC Control if no COM port is found on the computer. As soon as there is one (e.g. after installing an USB to serial adapter or activation of the on-board port), HC Control tries to communicate over this COM port.

Metrohm NOVA: Is the °C / min setting a temperature ramp control?

No, the °C / min parameter is not related to any temperature ramp control feature. Instead it is one of the temperature stability criteria. This means that the temperature should not vary more than x.xx °C / min after the set point has been reached. A temperature ramp feature is currently not included in the NOVA software. An alternative way is to set many different temperature values and reduce the hold time to e.g. 1 s and to set weaker temperature stability criteria. This emulates a kind of pseudo-ramp.

HC_Control and VersaStudio: Error message "HC_Control is already running"

If HC_Control is embedded into a VersaStudio routine using the "Run External Application" command, the "wait" parameter has to be set to "yes". HC_Control checks all stability criteria and closes, if all criteria are met. If the "wait" command in VersaStudio is set to "no", the routine advances without regard of temperature stabilization. This can lead to a second call of HC_Control.exe resulting in an error message.

HC_Control: Error message "XX.X is an invalid float"

The decimals of the temperature setpoint have to be separated by a comma.

Invalid format: 25.5 °C

Valid format: 25,5 °C

This is important when using the command line attributes.

RelaxIS: Can I also use arbitrary mathematical fit models instead of classical circuit elements?

Yes, you can. Models are implemented via "Circuit Element" plugins, using the RelaxIS SDK. The plugins can be created using the RelaxIS SDK Code Editor, which also contains a wizard for easy creation of Circuit Element plugins. Please also refer to the Basic Tutorial accessible from the SDK Code Editor.

A RelaxIS DLL-plugin I downloaded is rejected since it "is to be loaded from a network location". How can I fix that?

The problem is caused by a safety feature of Windows. Downloaded files are marked as such in the file system and additional restrictions for these files apply. To unblock the file, find the DLL in question in the Windows Explorer and right-click it. Select "Properties" from the menu. On the "General" tab find the button or checkbox (depending on Windows version) called "Unblock" or "Allow" and click it. Afterwards click OK. This removes the restriction from the file. WARNING: Please only use plugins from fully trusted sources! The plugins can execute arbitrary code and thus be malicious!

What methods for accessing the RelaxIS 3 license are available? Do I need to be online?

We offer two different methods for accessing your RelaxIS 3 license:

Sharing the license between multiple PCs can be accomplished by plugging the dongle into a (local) network PC that acts as a license server.

Dongle-based

We provide you with a USB hardware dongle. To start RelaxIS the dongle needs to be plugged into either the local PC or a PC in the local network. This method does not require you to be online and is the preferred method.Sharing the license between multiple PCs can be accomplished by plugging the dongle into a (local) network PC that acts as a license server.

Online access

As an alternative to the hardware dongle we offer accessing the RelaxIS license from our server via the internet. For this method we will provide you with login credentials that you use when starting RelaxIS. This method requires you to be online while using RelaxIS.

RelaxIS: Which license models are available?

All RelaxIS licenses define the number of concurrent users and are not bound to a specific PC or user. That means for example, for 2 licenses 2 PCs can use RelaxIS at the same time. Before a third PC can start RelaxIS, one of the other computers needs to shut RelaxIS down.

The available license models are:

The license does not renew automatically. It is not a subscription.

The available license models are:

Permanent license

You purchase a license and and can use it without limitations. You will receive all updates to the bought major version (e.g. RelaxIS 3) for free.Time-limited license

You purchase a license for a given amount of time. The price is determined by the number of month that you order. After the time has expired you can no longer use RelaxIS until the license is renewed. You will receive all updates to the bought major version (e.g. RelaxIS 3) for free.The license does not renew automatically. It is not a subscription.

RelaxIS: Is a trial version available?

Yes, we offer a free trial version of RelaxIS.

Please contact us via the contact form, or by adding the RelaxIS product to the cart and sending the request. We will then contact you for further details.

Please contact us via the contact form, or by adding the RelaxIS product to the cart and sending the request. We will then contact you for further details.

What is RelaxIS Portable?

RelaxIS Portable allows you to run RelaxIS without installation from a single directory. All runtime files like settings are stored in the same directory as RelaxIS itself. This is intended for systems where no administrator rights are available and you still want to use the latest RelaxIS version.

Important: You still have to install the Codemeter Runtime software once, which requires administrator rights. Once this software is installed, no administrator rights are required in the future.

Important: You still have to install the Codemeter Runtime software once, which requires administrator rights. Once this software is installed, no administrator rights are required in the future.

FAQ

FAQ